vickers hardness test theory|vickers hardness test manual : trading The fin attachment pins and sleeves in the Convair 580 airliner were specified by the aircraft manufacturer to be hardened to a Vickers Hardness specification of 390HV5, the '5' meaning five kiloponds. However, on the aircraft flying Partnair Flight 394 the pins were later . See more

WEB7 46,5K. Marcinha Caminhoneira - Mais na bio🔥 coxamac. 2 45,3K. MARCINHA CAMINHONEIRA MKZINN333. Marcinha Caminhoneira photos & videos. EroMe is the best place to share your erotic pics and porn videos. Every day, thousands of people use EroMe to enjoy free photos and videos.

{plog:ftitle_list}

WEB13 de out. de 2015 · O time gaúcho acabou campeão do torneio. Por isso, quando você receber a ficha técnica do jogo Lagartense 3 x 2 Fluminense, não se preocupe. .

vickers hardness test procedure pdf

design of tensile testing machine

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size . See moreIt was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter . See moreWhen doing the hardness tests, the minimum distance between indentations and the distance from the indentation to the edge of the specimen must be taken into account to avoid interaction between the work . See moreTo convert the Vickers hardness number to SI units the hardness number in kilograms-force per square millimeter (kgf/mm ) has to be multiplied with the standard gravity, $${\displaystyle g_{0}}$$, to get the hardness in MPa (N/mm ) and furthermore divided . See more

If HV is first expressed in N/mm (MPa), or otherwise by converting from kgf/mm , then the tensile strength (in MPa) of the material can be approximated as σu ≈ HV/c , where c is a constant determined by yield strength, Poisson's ratio, work-hardening . See more

The fin attachment pins and sleeves in the Convair 580 airliner were specified by the aircraft manufacturer to be hardened to a Vickers Hardness specification of 390HV5, the '5' meaning five kiloponds. However, on the aircraft flying Partnair Flight 394 the pins were later . See more• Indentation hardness• Leeb Rebound Hardness Test• Hardness comparison• Knoop hardness test See more• Meyers and Chawla (1999). "Section 3.8". Mechanical Behavior of Materials. Prentice Hall, Inc.• ASTM E92: Standard method for Vickers hardness of metallic materials (withdrawn and replaced by E384-10e2) See moreThe Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

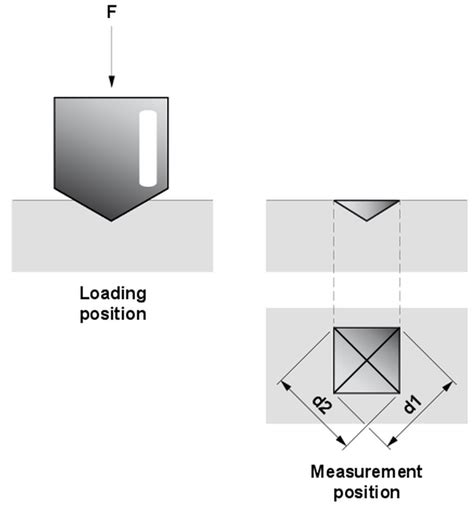

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). Originally developed by the Vickers Company of the United Kingdom in the 1920s to test alloy armor plates, the Vickers Hardness Test is still utilized to evaluate welded joints and heat-affected zones (HAZ) of metal .

vickers hardness test manual

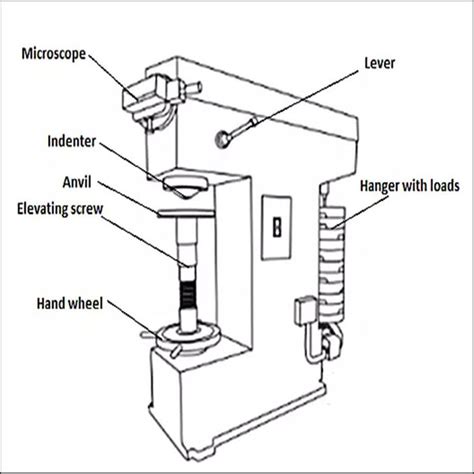

The Vickers hardness test is a static hardness test method, used for both macro and microhardness testing. It is an optical method of testing where the size of the indentation left by the indenter is measured to determine the hardness .Vickers hardness of ground and polished material was determined at room temperature for a series of load (100–500 gms) using a Leitz Durimet and at high temperature for a load of 500 .Find an overview of the Vickers methods and their applications depending on the load range as well as an explanation how to choose the right test load. (III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.

Learn more about hardness testing basics here. The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of . Theory: Hardness is a material characteristic which can be defined as resistance to deformationExamples: 450 HV 10 = Vickers hardness number of 450 obtained with a test force of 10 kgf, 700 HV 0.1 = Vickers hardness number of 700 obtained with a test force of 100 gf (0.1 kgf), 500 HK 0.5 = Knoop hardness number of 500 obtained with a test force of 500 gf (0.5 kgf). MICROINDENTATION HARDNESS TEST

Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is indicated by a higher HV. Vickers hardness values are a useful tool for comparing the hardness of various materials .A bench-based Vickers microhardness test machine (Figure 9.15) is similar in principle to a standard Vickers hardness tester, except much lower loads are used (between 1 and 1000 g) and, therefore, much smaller indents are formed into the specific region of interest. A similar principle is used in the Knoop hardness test, except that an .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .3.4 Vickers hardness test—an indentation hardness test using calibrated machines to force a square-based pyramidal diamond indenter having specified face angles, under a prede-termined force, into the surface of the material under test and to measure the diagonals of the resulting impression after removal of the force.

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials.United States 1 E92−17 C1326 Test Method for Knoop Indentation Hardness of 3.1.4 Vickers hardness number, HV,n—the calculated result Advanced Ceramics from a Vickers hardness test, which is proportional to the test C1327 Test Method for Vickers Indentation Hardness of force applied to the Vickers indenter divided by the surface Advanced .

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested. Instrumented indentation test, also known as nanoindentation test, has been widely used to evaluate the local indentation hardness of materials at the nano- and micro-scales for academic and industrial purposes; it has been frequently compared with the Vickers hardness (HV) test used on larger scales [].A considerable number of studies have .

VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester operates on the same basic principle as the Brinell tester, the numbers being expressed in the terms of load and area of the impression.the hardness value is calculated based on the applied load and the indentation size. Vickers belongs to the optical methods. Vickers Hardness The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thinThe Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search. The Basics of Vickers Hardness Testing. Vickers Hardness Testing is based on a straightforward principle: the depth or size of an indentation left by an indenter in a material is directly proportional to the material's hardness. The Vickers test employs a pyramid-shaped diamond indenter with a square base angle of 136 degrees.

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surfaceTheory: Refer to Mechanics of Material Laboratory manual for detail information. Summary of Theory: Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of the indenter.

Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.3.1.3 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.Vickers hardness testing, also called microhardness testing, is typically used for small parts, thin sections, or or case depth work. The Vickers method is based on an optical measurement system. The Microhardness testing procedure, ASTM E-384, specifies a series of light loads in which a diamond indenter makes an impression that is measured .1.1 Vickers Hardness. The Vickers test employs a square-based pyramid with an angle of 136° between opposing faces. The Vickers hardness is defined as the applied load P divided by the surface area of the impression. In general, the diagonal d or the depth t of the impression is measured and, .

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Adhesion theory and types. Wear of materials. Friction in materials .

The Vickers hardness number can provide insights into a material’s characteristics, such as its strength, toughness, and wear resistance. This makes it valuable for quality control, material selection, and failure analysis. When to Choose the Vickers Test: The Vickers Hardness Test is particularly suitable when:In the present study, the mass loss, dynamic modulus, cube compressive strength, micro-morphology and pore characteristic parameters of HBC concrete and reference specimens were investigated under freezing and thawing, and their internal frost damages were quantified by micro-Vickers hardness and ultrasonic theory. Test results showed that the .

web13 de out. de 2023 · ACESSE A YOUCINE:🍿🎥 https://appp.fyi/jujuONDE ME ENCONTRAR?😄Redes sociais:🟪DISCORD: https://discord.gg/yzJMYjc4ZR ️INSTAGRAM .

vickers hardness test theory|vickers hardness test manual